Reflow Master v2

Need to solder printed circuit boards using a specific temperature profile to match the solder paste? This is the solution!

Firstly a big shout out to Unexpected Maker https://unexpectedmaker.com/ who inspired this project with his Reflow Master. Published here on GitHub and licenced under CERN OHL 1.2. this allowed me to come up with modifications of my own to expand it's functionality.

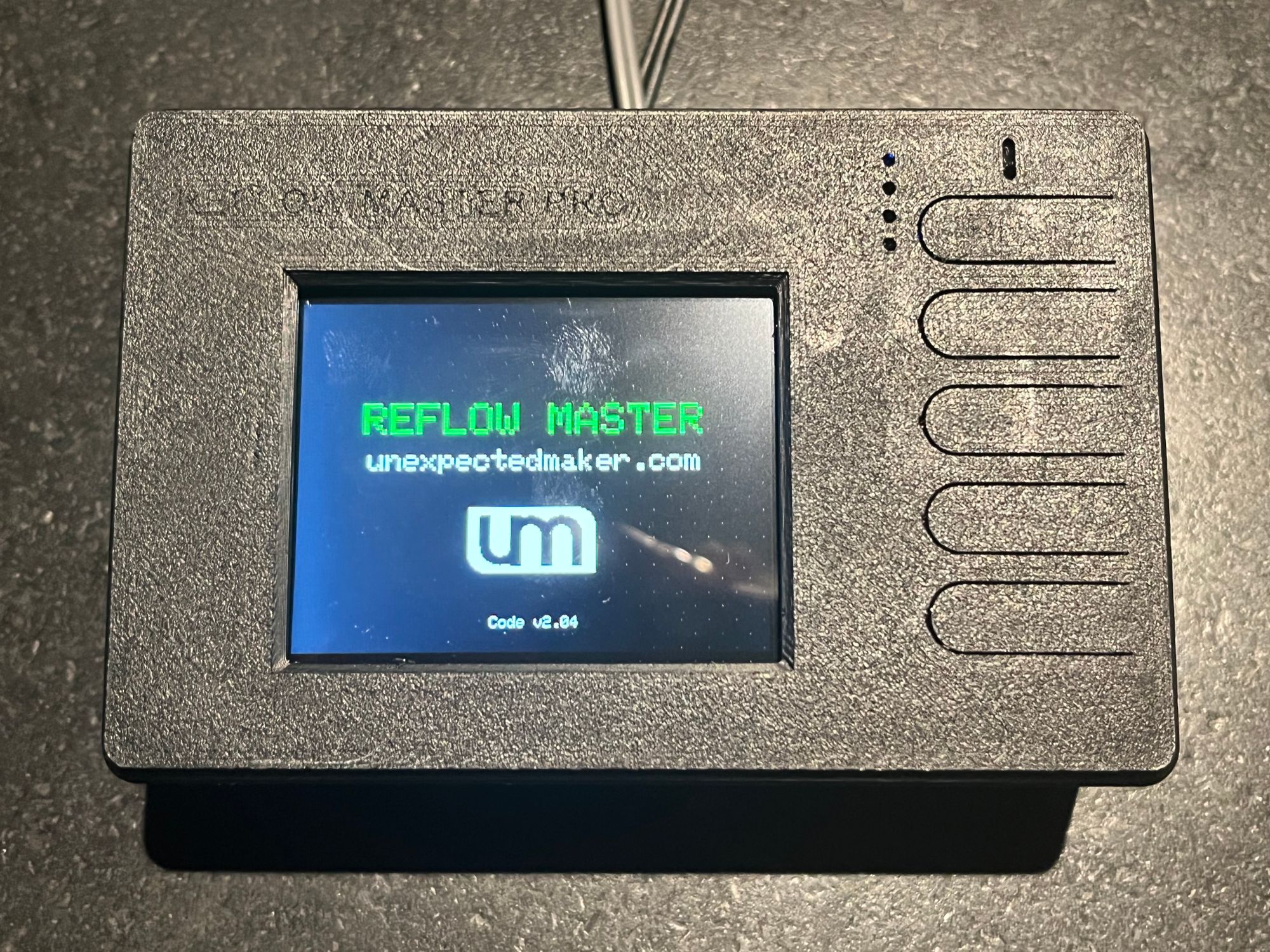

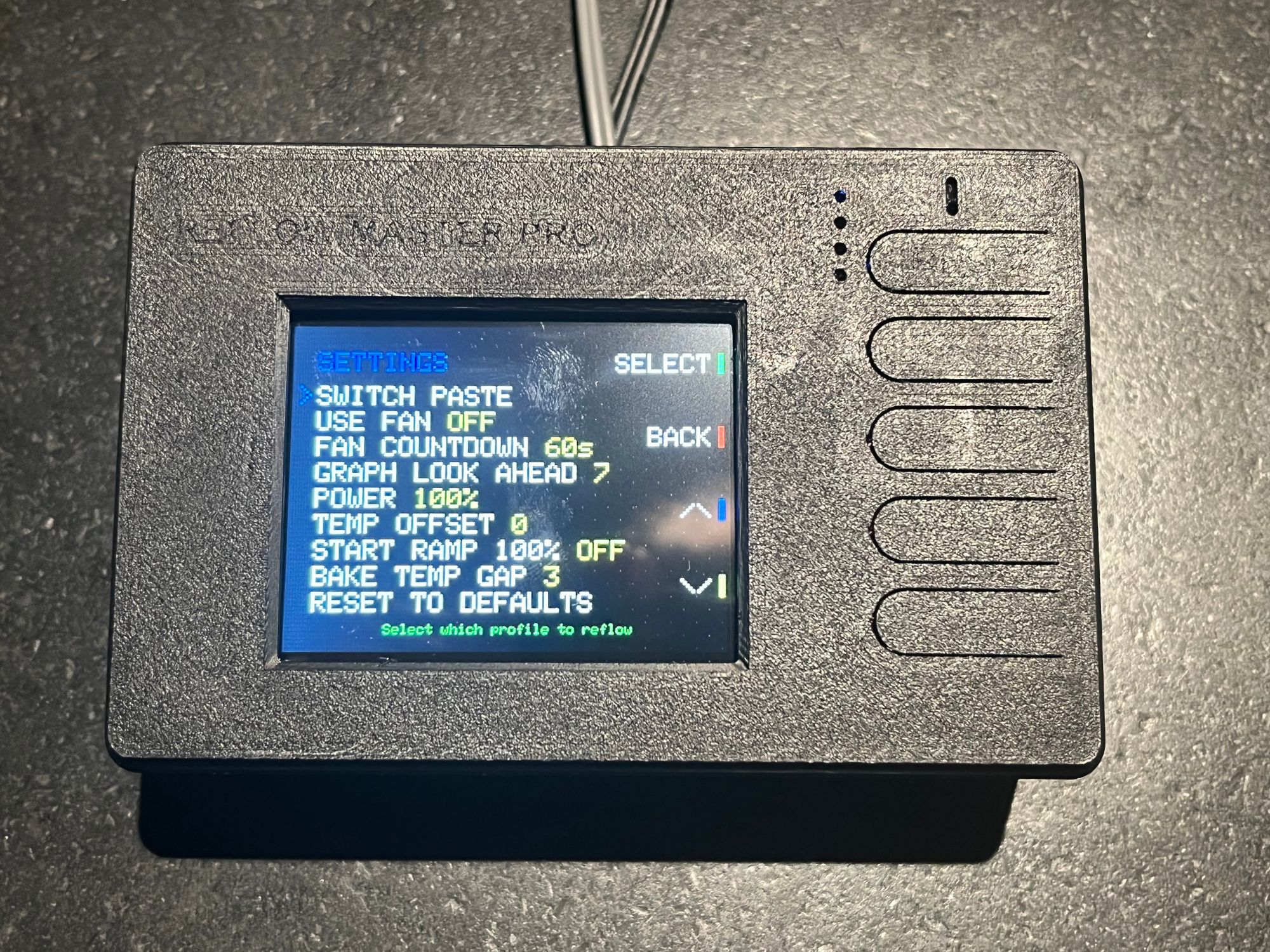

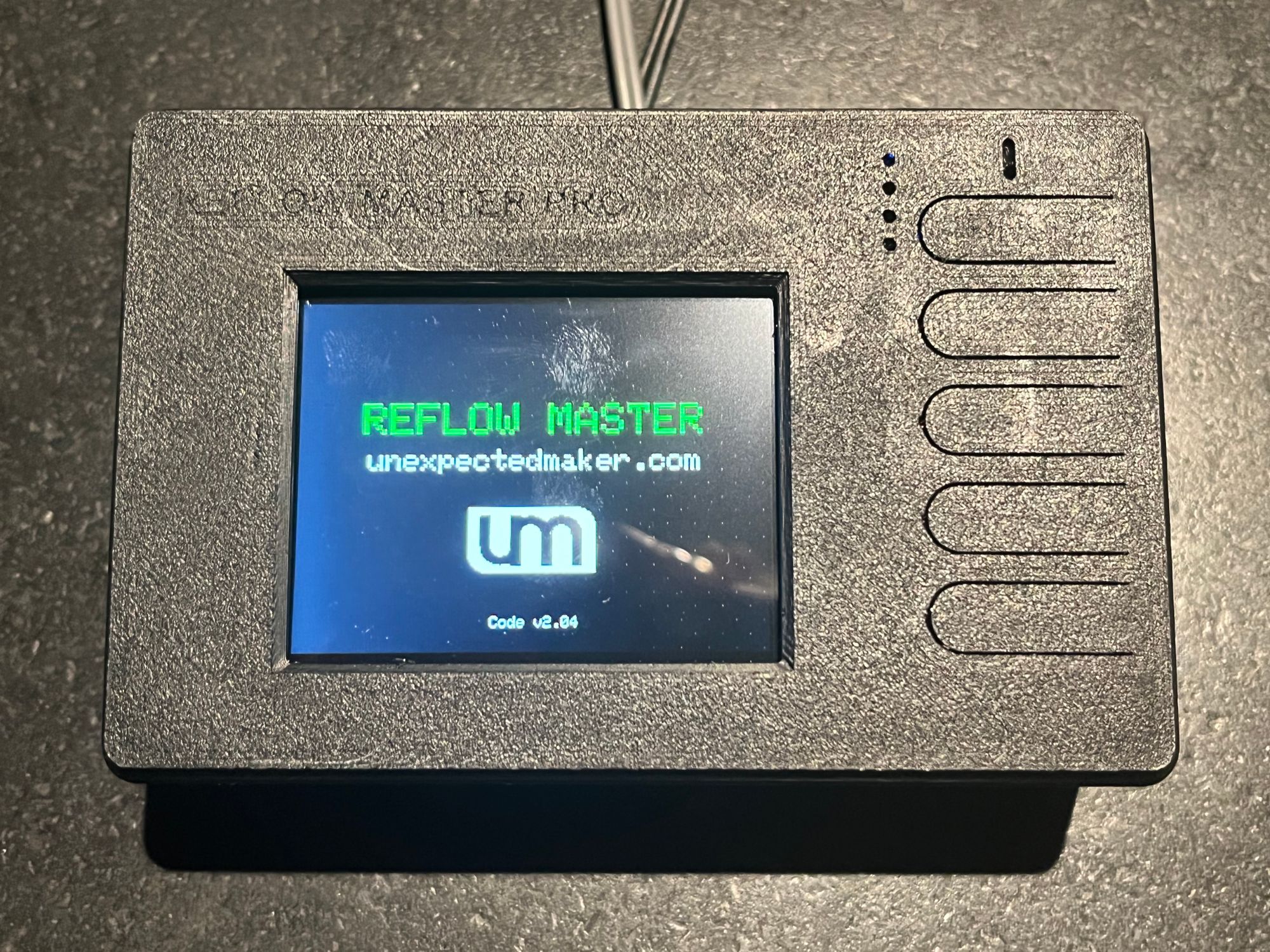

Unexpected Maker has since updated his design - I recommend ordering his "Reflow Master Pro" product to avoid needing a SAMD51 which this is based on! See https://reflowmasterpro.com/. I've also changed the name of this page to avoid confusion!

| Status | Prototype |

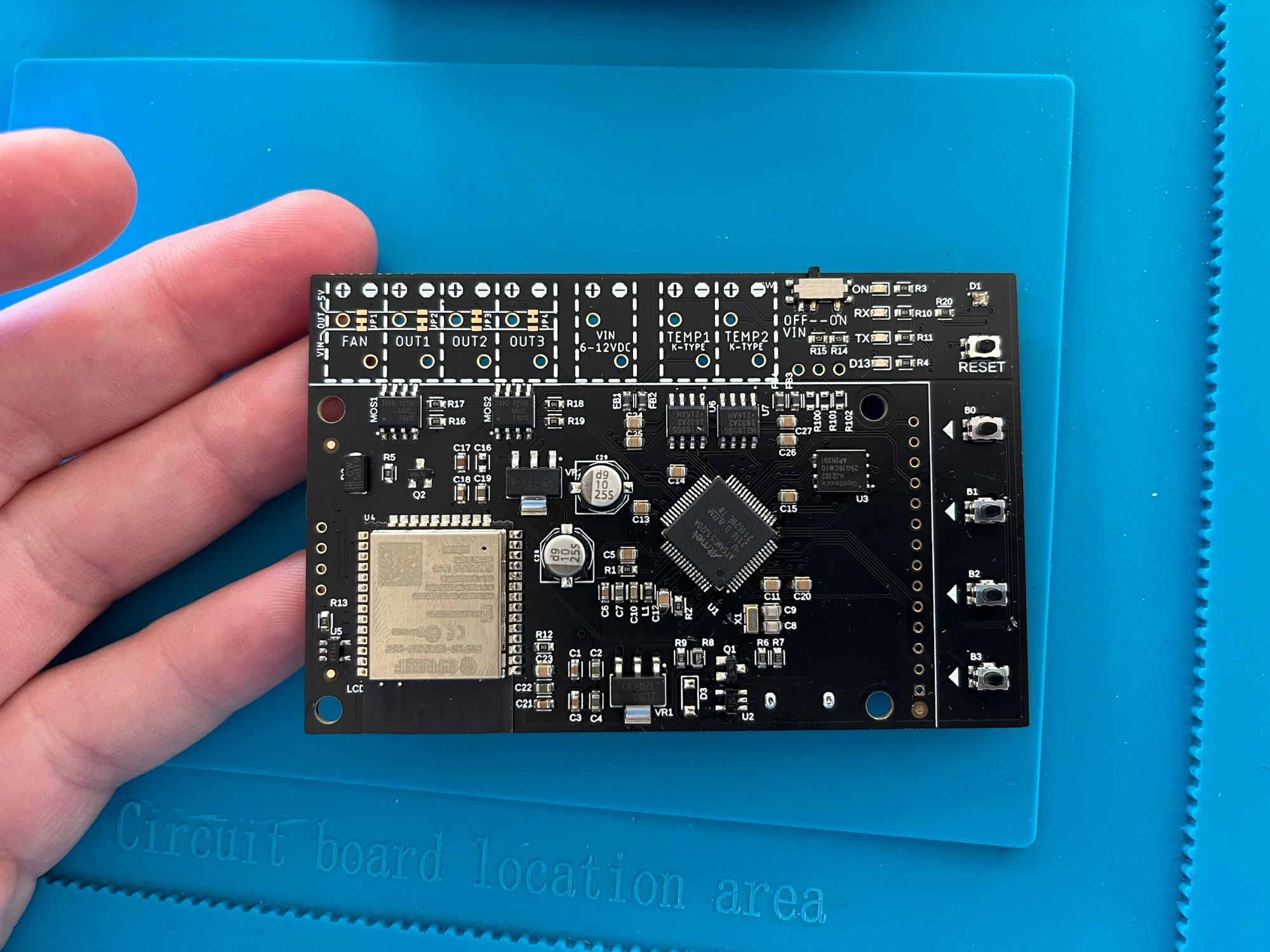

| Platform | ESP32 Custom PCB SAMD |

| Budget | $100 ea |

| Date Completed | May 2022 |

Summary of Operation

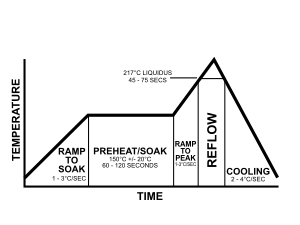

Reflow soldering is a process which requires the temperature of the printed circuit board (and the placed surface-mount components) to traverse a bespoke temperature profile that's specific to the solder paste used.

It's an amazing process to watch if you haven't seen it before. The melting solder and resulting surface tension pulls components into their correct orientation.

If you're interested in seeing some videos - search "reflow soldering" on YouTube. There's lots of examples, including this video by Great Scott which demonstrates a few different methods.

Here's a 30 second clip of reflow soldering the ESP-IO board. Notice the melting grey solder paste pulling items into location.

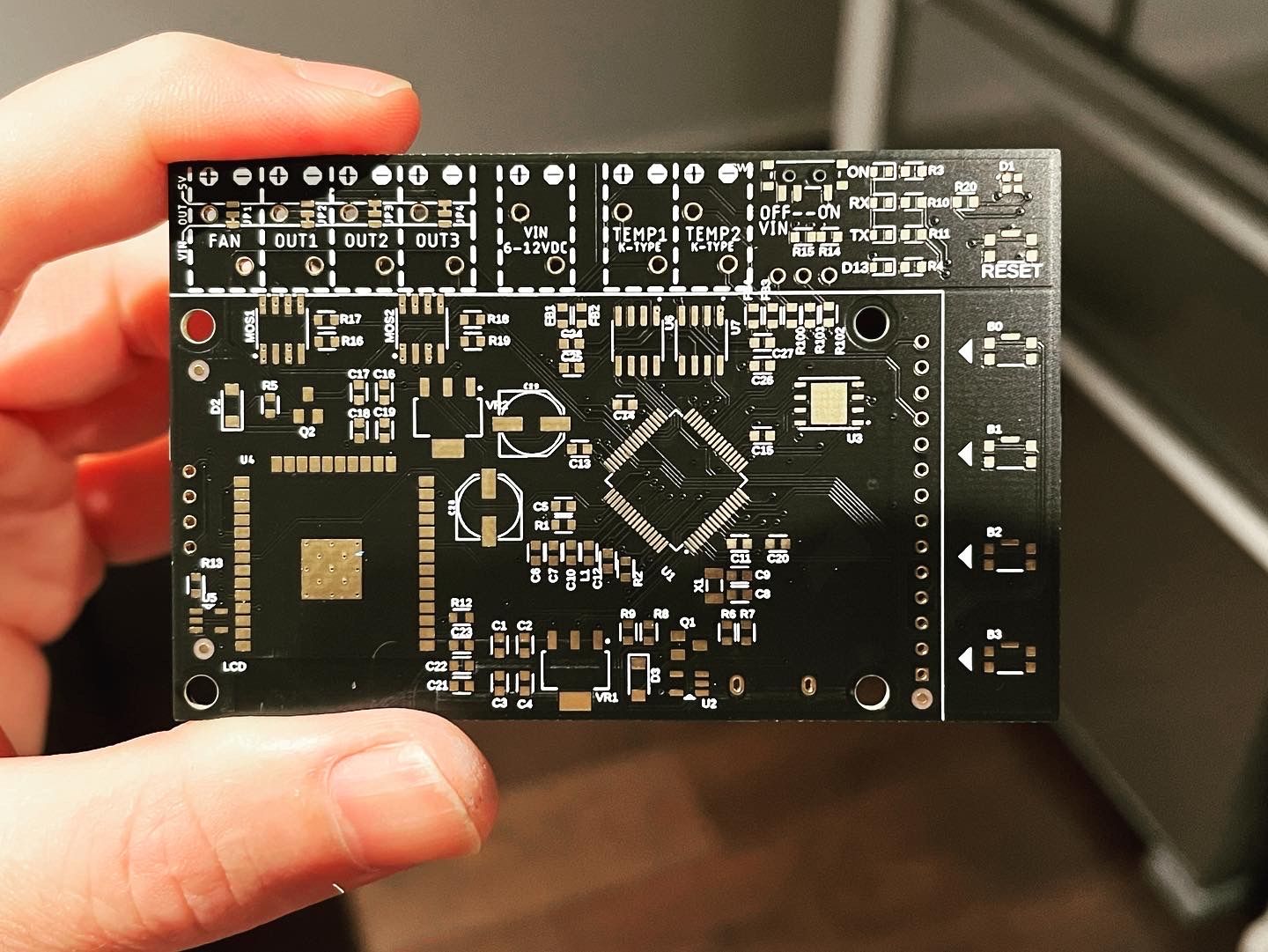

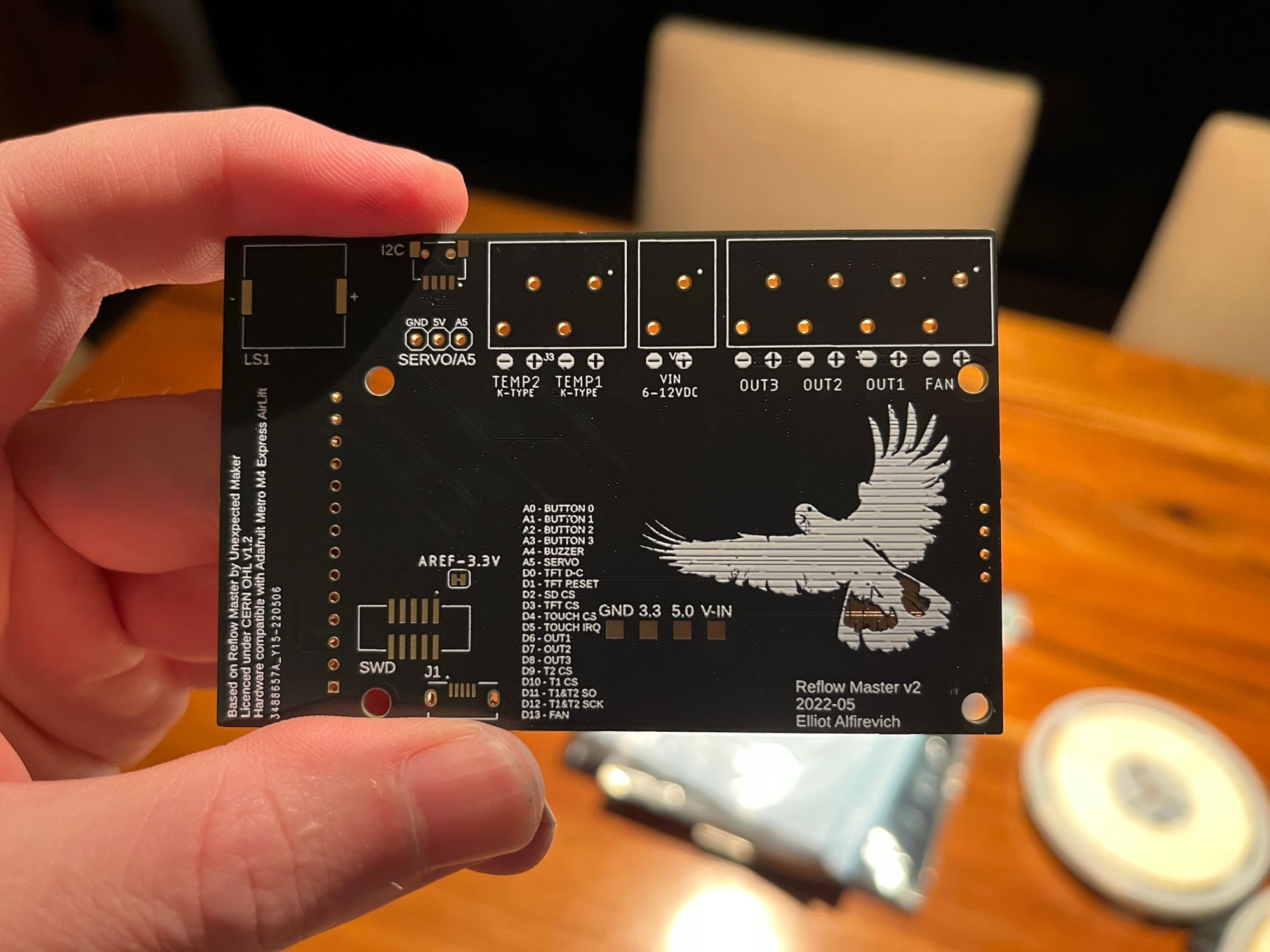

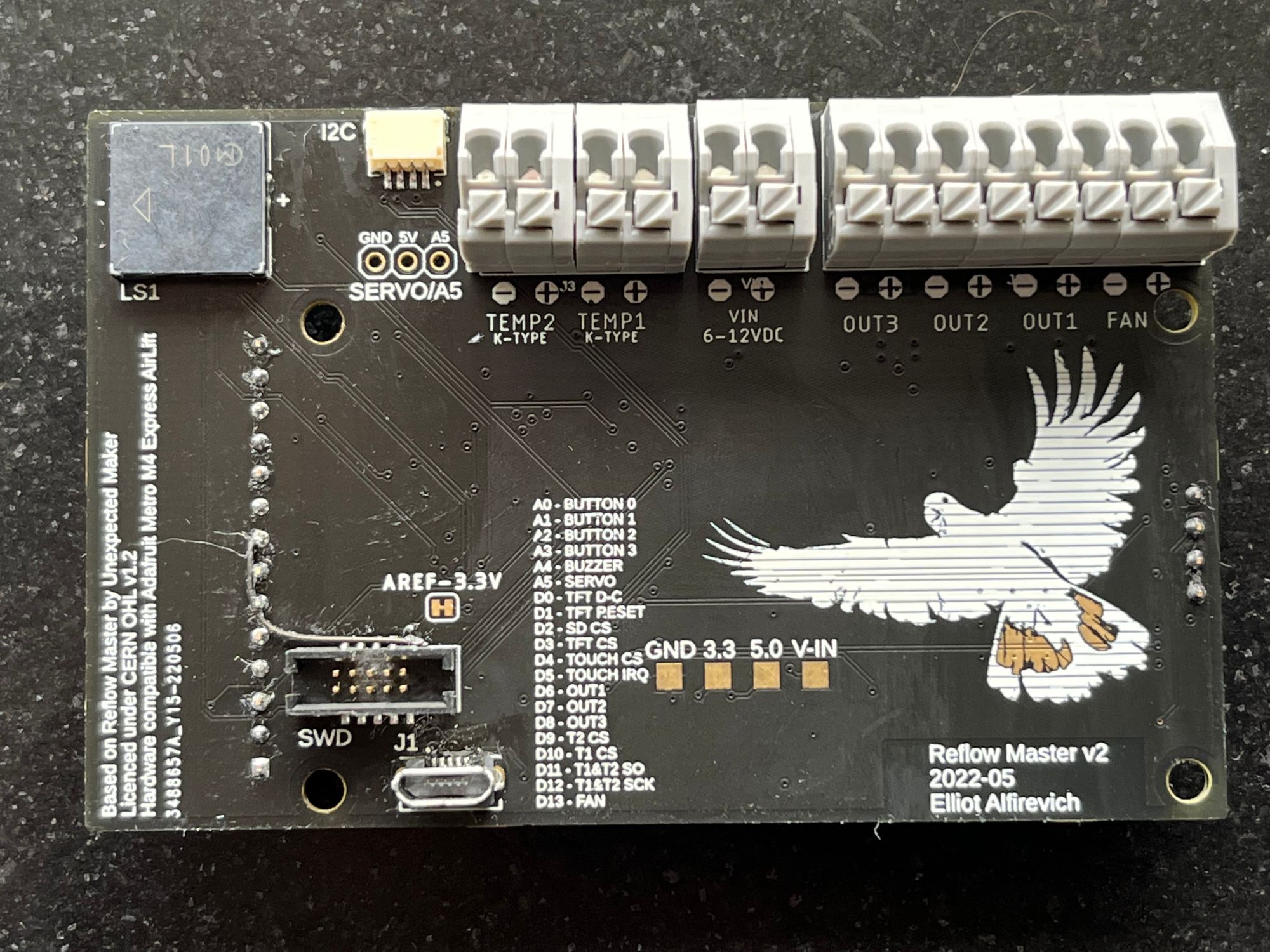

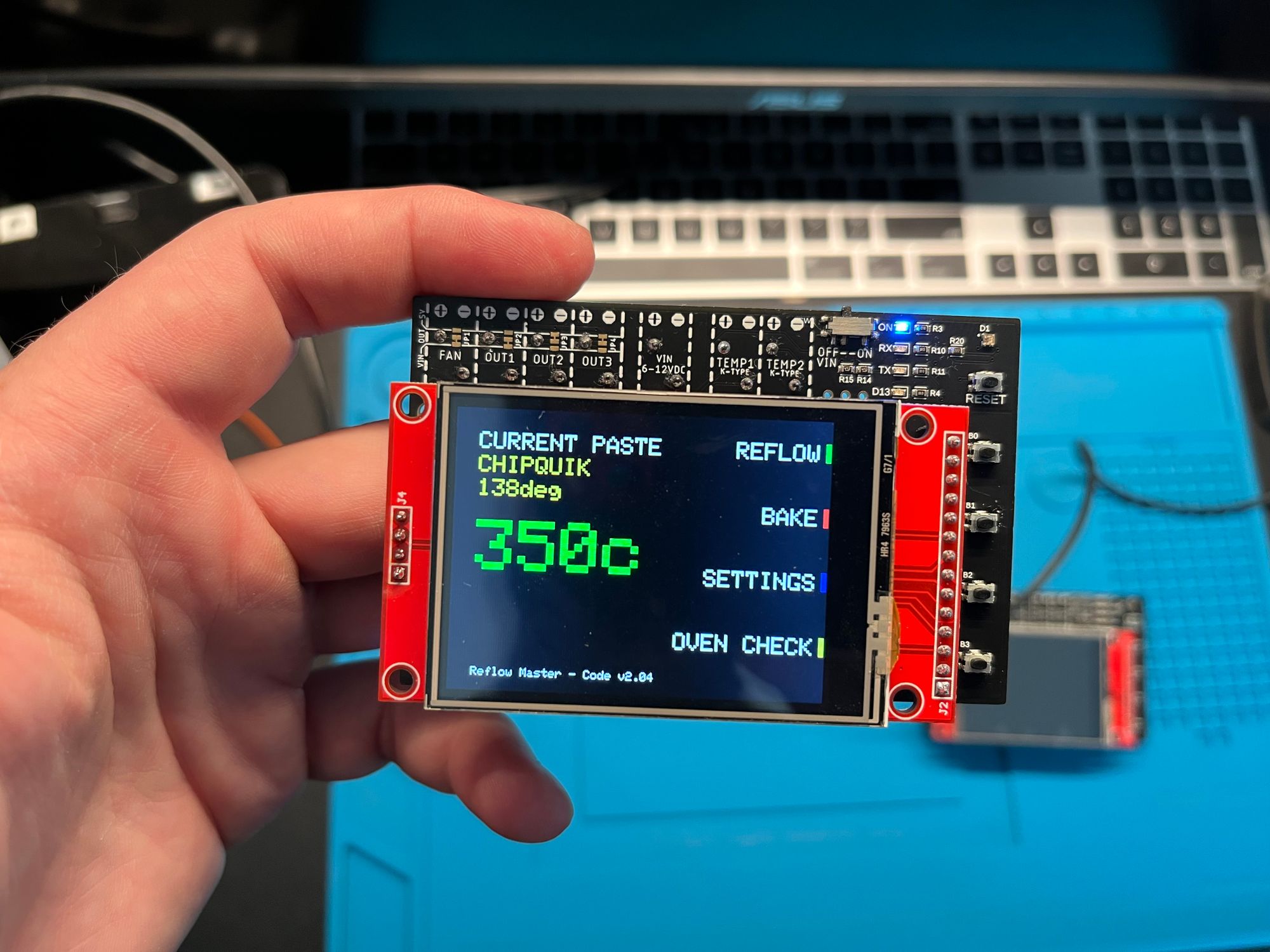

Here's some photos of the finished prototype - which was designed to be pin/hardware compatible with the Adafruit Metro M4 Express AirLift development board - giving a huge amount of out-of-the-box functionality to speed up code development.

Engineering Detail

So I wanted a few more inputs and outputs than the standard Reflow Master by Unexpected Maker. I wanted the ability to run heater and fan loads directly up to a couple of amps, as well as control external solid-state relays.

Why do I need the extra sensors and outputs? Because when I was making the larger Fuzzy Clocks I needed multiple heating elements and serious grunt to get them up to temperature given they were nearly 350x400mm size.

Here's a summary of the hardware design/comparision to the original Reflow Master by UM.

| Function | UM Reflow Master | Reflow Master v2 |

|---|---|---|

| Status | Production | Prototype only! |

| Host Platform | SAMD21 |

SAMD51 + ESP32 |

| Interface | 2.4in LCD | 2.4in LCD + Touchscreen |

| File storage | - | SD Card |

| Supply Voltage | 5V USB | 5V USB or 7-12VDC |

| Heating Outputs | 1x 500mA | 3x 5A |

| Fan Outputs | 1x 500mA | 1x 5A |

| Thermocouple Inputs | 1 | 2 |

| I2C Ports | - | 1x Stemma QT/QWIIC |

| Terminals | Screw | Würth Screwless |

All designed in Fusion 360/Eagle with a 3D printed enclosure (for now).

I will post the design on GitHub under CERN OHL 1.2 to honour the effort by Unexpected Maker and pay it forward! Just need to iron out a few bugs (you can see a fix wire on the back of it!)